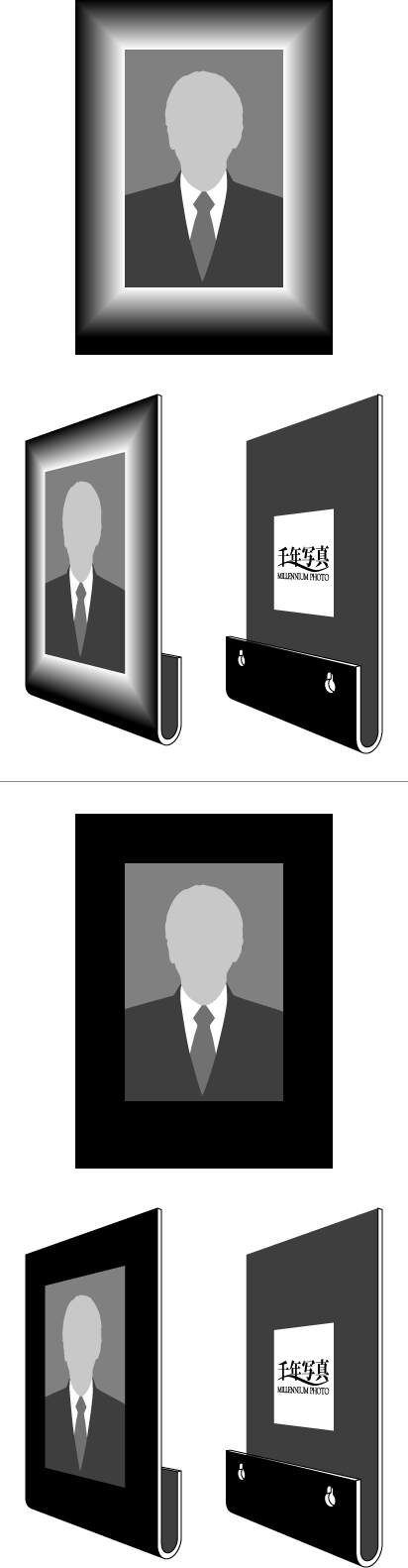

The prices of products of this type are set lower than those of the double-sided J-shaped type, by rolling only one side.

Products of this type are fixed on a wall or elsewhere by rolling a side of a single plate and drilling holes. This type is suitable for products to be installed indoors. The standard is to roll the bottom side; however, either the top, left or right side can be rolled instead.

As shown in the illustration, products cannot only be installed in parallel with the wall but also can be installed facing downwards by reducing the roll angle. It is also possible to have products facing up by changing the angle of the roll position by rolling the top side. Various arrangements can be made.

For structural reasons, it is not possible to increase the number of fixation sides for large-size products and it is necessary to hold the weight of products at 2 point, so the installation side may not be able to withstand the weight. Therefore, there is the maximum size for processing for products of this type.

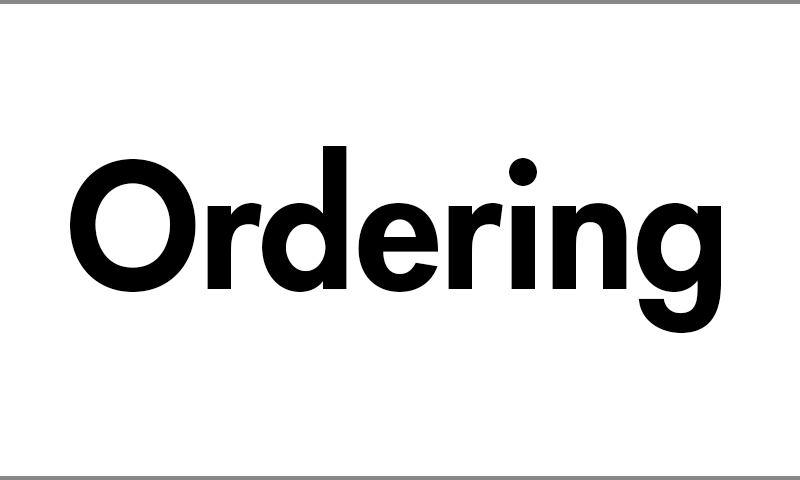

Image circumference processing

As shown in illustration, gradation margin and black margin are available. It is also possible to use the cut-off type which leaves no margin for the remaining 3 sides after rolling one side.

Please also select the Photo background pattern.

Installation method

The keyhole plus bolt method is the optimal installation method for this type.

For structural reasons, this type does not allow bolts and screws to be inserted into the product from the front side, and a box wrench cannot be used. A wrench or a monkey wrench is inserted from the side to rotate the bolts. In the case of the round holes plus bolt method, bolts cannot be used if their length would get stuck on the plate material. The length should be up to approximately 20mm, including their head part.

If it is possible to screw bolts into products from the reverse side of the wall, the round holes plus bolt method can also be used without limiting the length of bolts by tightening nuts from the side on the front. However, it is necessary to make adjustments using washers by checking the thickness of the wall and the length of bolts so that the bolt edge does not get stuck on the longer side of the J-shaped type.

The round hole plus anchor bolt method cannot be used with this type.